When it comes to choosing between laser cutting machines and traditional cutting methods (like mechanical saws, plasma cutting, waterjet cutting, or manual cutting), the right decision depends on your business needs, scale of production, material type, and quality expectations.

Laser cutting machines have revolutionized the manufacturing industry by offering precision, speed, and automation, but traditional methods still hold relevance due to their lower cost and simplicity.

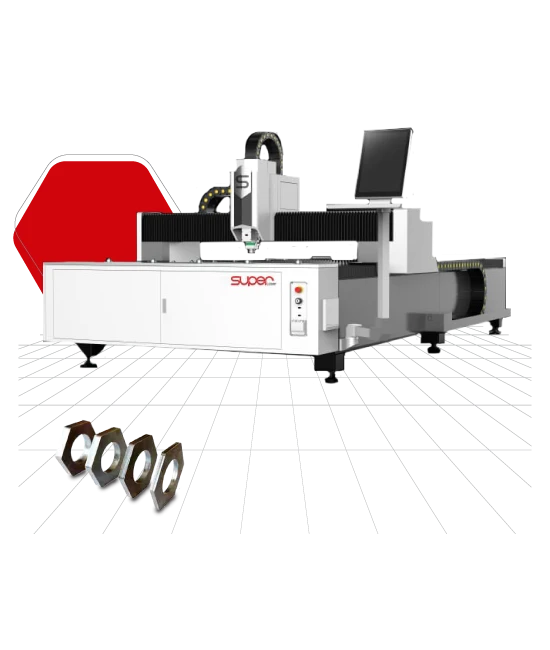

Laser cutting uses a concentrated beam of light to melt, burn, or vaporize material, providing high accuracy, clean edges, and minimal material wastage.

It is ideal for industries that demand intricate designs, fine detailing, and consistency, such as automotive, aerospace, electronics, and custom fabrication. Since laser cutting is computer-controlled, it ensures repeatability and supports automation for bulk production with less manual intervention.

Additionally, it works on a wide range of materials including metals, plastics, ceramics, wood, and composites. On the other hand, traditional cutting methods like mechanical saws or plasma cutters are more cost-effective in terms of initial investment and require less technical expertise to operate.

These methods are suitable for small-scale workshops, repair work, and businesses with low production volumes. However, they often result in rougher edges, higher wastage, slower processing times, and less design flexibility compared to laser cutting.

Maintenance and tooling costs may also be higher in the long run, especially for industries needing fine accuracy.